Drive and motor technology is a crucial factor in many industrial and commercial applications. Choosing the right motors and drives can greatly impact overall performance, affecting everything from efficiency and productivity to cost reduction and reliability. In today’s competitive business environment, it’s more important than ever to invest in the right drive and motor technology to help your business succeed.

In this article, we’ll explore the importance of reliable and efficient drive and motor technology in industrial and commercial applications. We’ll discuss the key factors to consider when choosing the right motor and drive for your specific needs, including efficiency, reliability, precision, and accuracy. Additionally, we’ll look at some of the different types of motors and drives available, and how they can be used to improve overall performance in various applications. By the end of this article, you’ll have a better understanding of the role that drive and motor technology plays in industrial and commercial settings, and how to choose the right motor and drive for your specific needs.

Efficiency: The Key to Cost Reduction

One of the most important factors to consider when it comes to driving and motor technology is efficiency. More efficient motors and drives can help businesses save energy and reduce operating costs. This is particularly important in today’s world, where energy costs continue to rise and businesses are under pressure to reduce their carbon footprint.

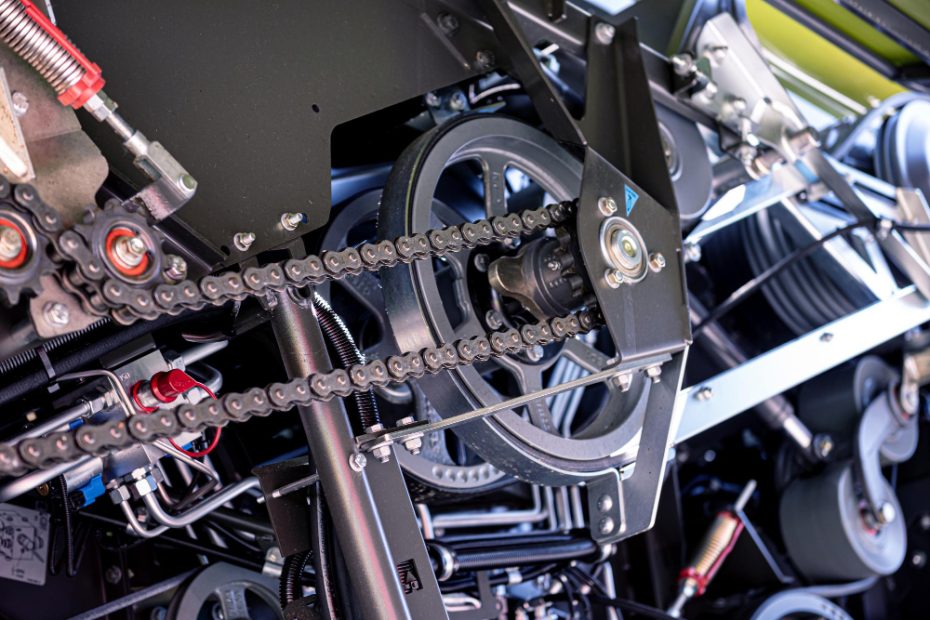

One of the ways to improve efficiency is by using variable frequency drives (VFDs), which can adjust the speed of the motor to match the load demand. This helps to reduce energy consumption and extend the life of the motor. Additionally, VFDs can help to reduce wear and tear on mechanical components, reducing maintenance costs and downtime.

Reliability: Ensuring Continuous Operations

Another important consideration when it comes to driving and motor technology is reliability. Downtime can be costly for businesses, so it’s important to choose drive and motor technology that is durable and can withstand harsh operating conditions. This will help to minimize the risk of breakdowns and ensure that operations continue to run smoothly.

One way to improve reliability is by using motors with high-quality bearings and seals. Additionally, it’s important to choose motors and drives that are designed to handle the specific demands of the application. For example, if the application requires high-speed, high-torque operations, it’s important to choose motors and drives that are designed to handle these demands.

Precision and Accuracy: Essential for Industrial Applications

Precision and accuracy are important factors in many industrial applications. For example, in a CNC machining operation, the accuracy of the motor and drive can directly affect the quality of the finished product. In these types of applications, it’s important to choose motors and drives that are designed for precision and accuracy.

One type of motor that is commonly used in precision applications is the servo motor. Servo motors are designed to provide accurate and precise control over the speed and position of the motor shaft. Additionally, servo drives can provide advanced features such as position feedback and automatic tuning, further improving precision and accuracy.

Choosing the Right Motor and Drive for Your Application

When it comes to choosing the right motor and drive for your application, there are several factors to consider. Some of the most important factors include:

- The specific requirements of the application, such as speed, torque, and precision

- The operating environment, including temperature, humidity, and exposure to dust or debris

- The required level of reliability and durability

- The availability of maintenance and repair services

AC motors, DC motors, and servo motors are all commonly used in industrial and commercial applications. Each type of motor has its own unique features and benefits. Similarly, there are several types of drives available, including VFDs, servo drives, and stepper drives. Each type of drive has its own unique features and benefits as well.

To choose the right motor and drive for your application, it’s important to work with a knowledgeable supplier who can help you evaluate your specific needs and recommend the best solution.

Conclusion

In conclusion, reliable and efficient drive and motor technology is essential for success in many industrial and commercial applications. Choosing the right motor and drive for your specific needs can greatly impact overall performance, including efficiency, productivity, and cost reduction. By considering key factors such as efficiency, reliability, precision, and accuracy, and exploring the various types of motors and drives available, you can ensure that you select the best option for your unique situation.

It’s worth noting that the drive and motor technology market is constantly evolving, with new advancements being made all the time. As such, it’s important to stay up-to-date on the latest developments in the industry, and to be willing to adapt your equipment and processes as needed. By keeping a pulse on emerging trends and technological innovations, you can continue to optimize your performance and stay ahead of the competition.